HURRICANE MITIGATION RETROFITS

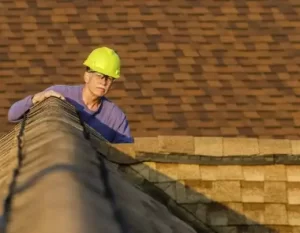

Lets talk about some of the importance of HURRICANE MITIGATION RETROFITS REQUIRED FOR EXISTING SITE-BUILT SINGLE FAMILY RESIDENTIAL STRUCTURES.

201.3 Roof-to-wall connections or hurricane mitigation retrofits are required for site-built single family residential structures. Where required by Section 101.2 511.4, the intersection of roof framing with the wall below shall be strengthened by adding metal connectors, clips, straps, and fasteners such that the performance level equals or exceeds the uplift capacities as specified in Table 201.3. As an alternative to an engineered design, the prescriptive retrofit solutions provided in Sections 201.3.1 through 201.3.4 shall be accepted as meeting the mandated roof-to-wall retrofit requirements.

201.3.1 Prescriptive method for gable roofs on a wood frame wall. Sufficient eave sheathing shall be removed to expose a minimum of 6-feet of framing members, measured from the corner, along the exterior wall on each side of each gable end. The anchorage of each of the exposed rafters or truss shall be inspected. Wherever a strap is missing or an existing strap has fewer than four fasteners on each end, approved straps, ties or right angle gusset brackets with a minimum uplift capacity of 500 lbs shall be installed that connect each rafter or truss to the top plate below. Adding fasteners to existing straps shall be allowed in lieu of adding a new strap provided the strap is manufactured to accommodate at least 4 fasteners at each end. Wherever access makes it possible (without damage of the wall or soffit finishes), both top plate members shall be connected to the stud below using a stud to plate connector with a minimum uplift capacity of 500 lbs.

201.3.2 Prescriptive method for gable roofs on a masonry wall. Sufficient eave sheathing shall be removed to expose a minimum of 6-feet of framing members, measured from the corner, along the exterior wall on each side of each gable end. The anchorage of each of the exposed rafters or truss shall be inspected. Wherever a strap is missing or an existing strap has fewer than four fasteners on each end, approved straps, ties or right angle gusset brackets with a minimum uplift capacity of 500 lbs shall be installed that connect each rafter or truss to the top plate below or directly to the masonry wall using approved masonry screws that will provide at least a 2-1/2 embedment into the concrete or masonry. When the straps or right angle gusset brackets are attached to a wood sill plate, the sill plate shall be anchored to the concrete masonry wall below. This anchorage shall be accomplished by installing ¼-inch diameter masonry screws, each with supplementary ¼-inch washer, having sufficient length to develop a 2-1/2 inch embedment into the concrete and masonry. These screws shall be installed within 4-4 inches of the truss or rafter on both sides of each interior rafter or truss and on the accessible wall side of the gable end truss or rafter.

201.3.3 Prescriptive method for hip roofs on a wood frame wall. Sufficient corner eave sheathing shall be removed from the side of the hip ridge parallel to the roof ridge to provide access to a minimum 6-foot length of the exterior wall. The hip ridge board and any exposed rafters that are not anchored with a strap having at least four fasteners on each end, shall be connected to the top plate below using a strap or a right angle gusset bracket having a minimum uplift capacity of 500 lbs. Adding fasteners to existing straps shall be allowed in lieu of adding a new strap provided the strap is manufactured to accommodate at least 4 fasteners at each end. Wherever access makes it possible (without damage of the wall or soffit finishes), both top plate members shall be connected to the stud below using a stud to plate connector with a minimum uplift capacity of 500 lbs.

201.3.4 Prescriptive method for hip roofs on a masonry wall. Sufficient corner eave sheathing shall be removed from the side of the hip ridge parallel to the roof ridge to provide access to a minimum 6-foot length of the exterior wall. The hip ridge board and any exposed rafters that are not anchored with a strap having at least four fasteners on each end, shall be connected to the concrete masonry wall below using approved straps or right angle gusset brackets with a minimum uplift capacity of 500 lbs. Adding fasteners to existing straps shall be allowed in lieu of adding a new strap provided the strap is manufactured to accommodate at least 4 fasteners at each end. The straps or right angle gusset brackets shall be installed such that they connect each rafter or truss to the top plate below or directly to the masonry wall using approved masonry screws that will provide at least a 2-1/2 embedment into the concrete or masonry. When the straps or right angle gusset brackets are attached to a wood sill plate, the sill plate shall be anchored to the concrete masonry wall below. This anchorage shall be accomplished by installing ¼-inch diameter masonry screws, each with supplementary ¼-inch washer, with sufficient length to develop a 2-1/2 inch embedment into the concrete and masonry. These screws shall be installed within 4-inches of the truss or rafter on both sides of each interior rafter or truss and on the accessible wall side of the gable end truss or rafter.

201.3.5 Priorities for mandated roof-to-wall retrofit expenditures. For houses with both hip and gable roof ends, the priority shall be to retrofit the gable end roof-to-wall connections unless the width of the hip end is more than 1.5 times greater than the width of the gable end. Priority shall be given to connecting the corners of roofs to walls below where the spans of the roofing members are greatest.